How Manufacturers Can Avoid COVID-19 Lockdown in 2021

Do you dread the day you’ll be compelled to suspend your manufacturing operations due to COVID-19 restrictions?

Imagine, one day you get to work, only to find a letter in the mailbox, telling you it’s time to shut down your manufacturing facility within the next 24 hours.

Well, this has become the norm in recent times as the world grapples with the effects of the Coronavirus.

Manufacturers are now struggling with massive job cuts, high production costs, reduced income, and declining demand for products.

To make matters worse, many manufacturers lack the tools to detect and prevent COVID-19 outbreaks, subsequently forcing many facilities to shut down prematurely.

The good news is that there are various tools you can use to prevent the lockdown of your facility.

In this article, we explore the impact of COVID-19 on the global manufacturing industry and how to mitigate the risks that arise as a result.

Here’s an outline of what we will cover:

- Impact #1: Unscheduled and Mandated Facility Closures

- Impact #2: Supply Chain Disruptions

- Impact #3: Declining Industrial Activity

- Impact #4: Global Decline in Aggregate Demand

- Impact #5: Disruption of Labor Supply

- Impact #6: Decreased Consumer Confidence

- Impact #7: Reduced Access to Credit Markets

- Impact #8: Reduced Capital and Operational Expenditure

- Impact #9: Increased Production Costs

- Impact #10: Unplanned Rearrangement of Factory Floor Plans

- Building an Action Plan to Manage the Impact of Covid-19 on the Manufacturing Sector

- Impact #1: Unscheduled and Mandated Facility Closures

One of the most significant effects of the COVID-19 global pandemic has been the forced closure, albeit temporarily, of most manufacturing facilities around the world.

Various nations have enforced strict measures and regulations to control the spread of this highly infectious virus, to avoid overwhelming the already overstretched health care systems.

Lockdowns and mandated closures have been the norm in recent times as industries struggle with crippled operations and massive job losses.

In a bid to comply with these strict guidelines, big automakers like Volvo, Toyota, and Volkswagen have suspended operations in their facilities in North America. Other industrial manufacturers are following suit by shutting down their production plants, with no clear resumption dates set.

The unscheduled and mandated facility shutdowns are almost inevitable since the manufacturing industry is yet to adopt remote working strategies. In any case, it is challenging for factory workers to perform their duties remotely since most of the work requires an onsite approach.

Listen closely. With over 53% of manufacturers anticipating a change in operations due to COVID-19, enforcing health guidelines and equipping your workforce with the right tools can go a long way in protecting your business, workers, and assets.

- Impact #2: Supply Chain Disruptions

Did you know that 35.5% of manufacturers are facing supply chain disruptions? This is according to a special survey by the National Association of Manufacturers. Although the survey captured a small sample, it paints a grim picture of what is happening on the ground.

COVID-19 has triggered the first global supply chain crisis, as manufacturers grapple with lockdowns and travel restrictions. The supply chain disruptions have forced many companies to look for alternative suppliers outside the most affected regions.

The US-China trade war spells more gloom for manufacturers, as the two countries continue to battle for supremacy, on the global stage. With over 75% of US companies having at least one top tier supplier in China, all seems lost as a result of the worldwide pandemic coupled with the endless trade wars.

This calls for manufacturers to become more innovative and resilient by investing in gadgets that can help keep their supply chains intact.

- Impact #3: Declining Industrial Activity

As the coronavirus takes its toll on the global economy, we are observing a sudden decline in production activity. The sounds of machines roaring and cranes zooming are rapidly ceasing as manufacturing output growth continues to decline at 6 percent.

The reason for this is that many manufacturers are downsizing their workforce to reduce the number of workers on-site at any given time. This is a way of curbing the spread of the disease by enforcing social distancing restrictions.

Nevertheless, many businesses cannot maintain these containment measures for long, as it means they would have to contend with reduced output and a lower income. Some would even be forced to shut down due to the unfavorable economic environment.

- Impact #4: Global Decline in Aggregate Demand

Have you noticed that there is a slowdown in demand for industrial products and high-value durable goods?

Well, the sudden decline in demand is a result of several factors linked to the Covid-19 pandemic, including reduced industrial activity, the reshuffling of global supply chains, and facility closures.

When the aggregate demand shifts to the left, the economy contracts, meaning people will be earning a less disposable income than usual, leading to reduced demand for manufactured goods.

To mitigate the slowdown in aggregate demand, governments, and relevant agencies may introduce rebates and job programs, which may influence spending levels in the long-term.

Manufacturers can contribute to this by protecting their workforce using PPEs and other tailored equipment, ensuring an increase in industrial activities and preventing mandated facility closures.

- Impact #5: Disruption in Labor Supply

“Without labor, nothing prospers.” – Sophocles

Sophocles, the famous Greek dramatist, got it right when he said nothing could prosper without labor.

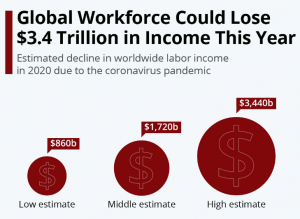

As the world battles a significant health crisis, many countries have had to deal with massive job cuts and rising unemployment rates. The manufacturing industry is undeniably the worst hit as far as labor disruptions are concerned.

This results from the mandated facility closures and work-at-home directives issued by the respective authorities.

With a reduced supply in labor, many firms are now facing challenges to break even. Since it is hard for manufacturers to work remotely, many of them have opted to either suspend their operations or shut down completely.

Fortunately, this does not have to be you. One way to avoid labor disruptions is to invest in equipment that can help your firm adhere to COVID-19 guidelines.

A device like smartspace will ensure you follow the social distancing rules, meaning you do not have to send your workforce home. This will guarantee a better ROI in the long term amid the global crisis.

- Impact #6: Decreased Consumer Confidence

In case you haven’t noticed, consumers are spending less on manufactured goods, at the moment. This is primarily due to the uncertainty and economic downturn brought about by COVID-19. This means that manufacturers are set to witness huge losses during this financial year.

Fortunately, all is not lost, and you can help build consumer confidence during the pandemic using the following strategies:

- Incorporating containment measures in all your manufacturing processes

- Complying with health and safety guidelines

- Investing in Covid-19 tracking equipment

- Ensuring the production of quality products even as manufacturers struggle with high production costs

- Sharing your response to the COVID-19 pandemic

- Responding and engaging your customers on virtual platforms

- Impact #7: Reduced Access to Credit Markets

The onset of COVID-19 has caused anxiety over the financial markets. It is becoming increasingly difficult for manufacturers to access credit facilities. This spells trouble for small-scale and medium-scale manufacturers who largely rely on credit to cover production costs.

Nonetheless, organizations, such as the International Monetary Fund have opted to increase funding to help governments cushion manufacturers against the effects of COVID-19.

The worst-hit manufacturing firms can now expect support from their respective governments. However, to access this funding, the firms have to comply with various containment measures, such as social distancing and contact tracing.

Therefore, you have to invest in tools like smartspace to track interactions, monitor real-time data, and enforce social distancing rules.

- Impact #8: Reduced Capital and Operational Expenditure

Like any other industry, the manufacturing sector is set to witness a reduction in both capital and operational expenditures during this period of global turmoil. This means that firms will have less money to spend on rent, salaries, business expansion, and new assets.

The reasons for these reductions involve reduced cash flow. Consequently, manufacturing firms must come up with practical measures to ensure that their businesses survive the pandemic. One way to do this is to ensure that your labor force is not disrupted during these tumultuous times.

- Impact #9: Increased Production Costs

Following global supply chain disruptions and negative trade patterns, it is only too obvious that the cost of production is set to rise if it hasn’t already. Manufacturing firms are staring severe losses in the face due to rising production costs.

According to the Chinese National Bureau of Statistics, the cost of manufacturing motor vehicles, general machinery, railways, and textiles rose significantly as the impact of COVID-19 is starting to become evident.

With China as one of the leaders in the manufacturing industry, other countries were also sure to be heavily impacted by the pandemic, and it would probably take a long time before the affected sectors recover.

- Impact #10: Unplanned Rearrangement of Factory Floor Plans

As you can probably imagine, factories are usually crowded with tools, heavy machinery and equipment, and of course, workers. Now, these crowded spaces are the perfect environment for the coronavirus to thrive.

In line with the set restriction guidelines, policymakers require manufacturers to enforce various containment measures to control the spread of COVID-19. One of these measures is social distancing.

Now, enforcing social distancing in a factory setting can be a huge challenge. It means that the manufacturer must rearrange the factory floor plans to comply with the “new normal”. This can be somewhat costly, especially if you have a shoestring budget for miscellaneous expenditures.

Then again, manufacturing is a process that requires workers to collaborate closely and, therefore, social distancing may prove difficult if you do not have the proper equipment to monitor these measures.

Building an Action Plan to Manage the Impact of COVID-19 on the Manufacturing Sector

“Great things are done by a series of small things brought together” – Vincent Van Gogh

Like going to battle, building an action plan is pivotal to managing the effects of COVID-19 on your manufacturing business.

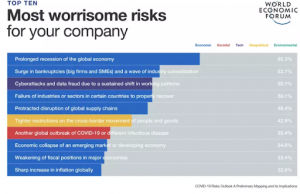

COVID-19 remains among the top 10 most concerning risks for companies in 2021. With the right plan, you can overcome the challenges that this pandemic has caused for your business.

Some of the most effective ways to cope with the effects of the Coronavirus include:

- Adhering to containment measures set by the government

- Improving social distancing practices

- Reducing employee anxiety

- Investing in tools and equipment to help track and detect containment measures

Many manufacturers do not know that there are tools they can use to detect and track COVID-19 outbreaks. Using these tools can go a long way in helping to reduce the number of employees who have to self-isolate while preventing mandated lockdowns.

So what’s the next step?

“The future of manufacturing is in technology. The next generation of manufacturing champions will come from those companies that use brainpower, not labor, to drive their innovations.” – Steven Moore

Although many manufacturers are struggling with forced closures, labor supply disruptions, reduced demand, and high production costs, you can protect your firm from the effects of COVID-19. With every challenge comes an opportunity to accomplish something great.

Instead of dwelling on old, outdated strategies, you should embrace innovative technologies that can help shield your business and workforce during this time and beyond.

One piece of technology that comes to mind is smartspace by SeguroLLC. This unique gadget comes in handy in the fight against COVID-19. It tracks interactions and triggers a warning when someone gets too close. You can also track who has been in contact with whom at any given time.

What is even more interesting is that smartspace is not only meant for use as a COVID-19-pandemic product. It can be used for other traceability applications, such as the prediction of flu and changes in weather patterns.

Try the smartspace device and let us know how it goes. After all, “continuous improvement is better than delayed perfection.” Mark Twain

Sorry, the comment form is closed at this time.